Hydro-Water Jetting

The What Of Hydro-water Jetting:

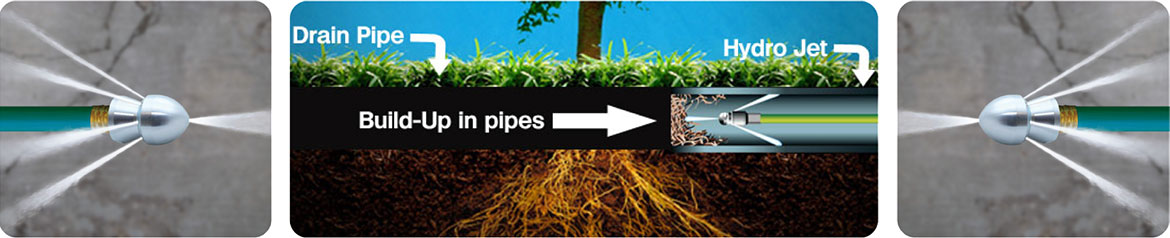

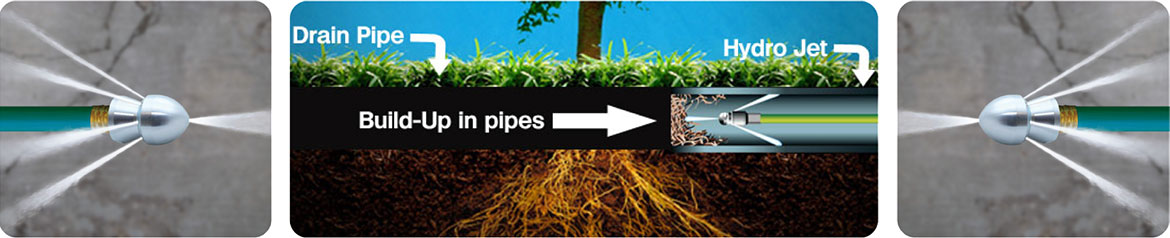

Water jetting uses high pressure water to blast through heavy blockages in sewer and drain lines. Water Jetting has the power and speed to break through the toughest of blockages and cleans across the entire diameter of the pipe. Water jetting is a more effective way to clear sewer and drain line obstructions such as tree roots, grease, mineral deposits, and waste build up. While cable machines only push through obstructions, water jetting thoroughly cleans and flushes the debris out of the line without damaging the infastructural integrity of the surrounding area.

Restaurants and commercial facilities typically require sewer jetting, due to frequent usage and the size of the sewer and drain lines. Grease is often the cause of line blockages. Water jetting can also be used to clear line blockages for residential as well as municipal establishments.

Water Jetting Explained:

Water jetting equipment holds hundreds of gallons of water. The flexible hose with special nozzle is attached to high pressure water tanks. Water is pumped through the hose under varying amounts of pressure into the drain line. The special nozzle is engineered to distribute jets of water in a forward and reverse motion. The high pressure water streams break up blockages and wash out debris from the line at the same time.

How You Can Save Money With Hydro-water Jetting:

Maintaining sewer and drain lines regularly reduces emergency service fees and down time. Our preventative maintenance plans are designed to save you money and are offered at a special discounted rate.

Regular preventative maintenance plans can be scheduled on a monthly, quarterly, or yearly basis. Set up a preventative maintenance plan with us today.

CIPP Sewer & Drain Repair

The What Of CIPP Sewer & Drain Repair:

Trenchless Sewer Repair is an alternative to sewer drain and rainwater pipe replacement commonly referred to as Cured-In-Place Pipe (CIPP). CIPP is where a pipe is created within the existing pipe with special epoxy resins creating the structural strength of new pipes without damage to the surrounding area. There are two primary types of applications, the pull-in-place(PIP) method and the inversion method.

How CIPP Sewer & Drain Repair Works:

- Identification of the problem by video camera inspection. Through a video camera inspection, we can identify the issue and recommend the best solution for the specific problem.

- Cleaning the sewer lines thoroughly. Once the problem and solution are identified, we clean out all waste and blockages in sewer line by high pressure water jetting in order to return the pipe back to its best functionality and diameter. Cast pipe may require additional preparation if the pipe is badly corroded.

- Inspection of the pipeline following high pressure water jetting. After water jetting the pipeline, it is important to inspect the line once more and visually ensure proper CIPP installation conditions.

- Installation of the CIPP liner. The exact length of liner needed is cut; a custom two-part epoxy is mixed and poured in to the felt liner. The custom two-part epoxy is then rolled throughout the liner ensuring proper and even saturation. Then the liner is pulled in place, or air pressure inverted, the callabration tube or bladder is inflated and the curing begins. Once the epoxy lining has cured, the bladder is extracted, leaving a complete structural sound pipe within the original pipe. To insure that the job has been performed perfectly, a video camera inspection is done to inspect the work, and we provide a copy of this to you as well.

Our CIPP Lining is GUARANTEED FOR LIFE.